Environmental efficiency

CHANGES IN EXHAUST GASES

this is a consequence of the operation of the “Super Torque” Pulse Module, which, along with the Fuel and Dynamic efficiency of the Module, is measured objectively/instrumentally/ and is the Environmental Efficiency of the “Super Torque” Module, one of the three main Advantages of the FPDtech Technology.

What does the emergence of a new innovative tool and technological

Hydrocarbon Footprint Reduction Factor

in the Fuel Vehicles sector.

Process description:

after installing/connecting the “Super Torque” Pulse Module, due to a decrease in the power load on the crankshaft of the internal combustion engine, each single dosage of the Air-Fuel Mixture is reduced, which is characterized by more complete combustion of the Air-Fuel Mixture.

This is the key point and the main reason

the subsequent launch of the process of more complete afterburning of unburned hydrocarbon residues of military-technical vehicles, during which a short-term increase in the percentage of toxins is noted in the composition of the exhaust gases.

Further, with the correct operation of serviceable sensors, the system, in cases where this mode is provided, is capable of forcibly increasing the VTS dosage as a programmatic response to an increase in toxins in the exhaust. Launching such a mode is

Objective Confirmation

reducing the one-time fuel dosage of VTS

due to a decrease in the force load on the internal combustion engine crankshaft;

the termination of this regime, in most cases, occurs 1200-1500 kilometers after installing the “Super Torque” Pulse Module until, if possible, the complete afterburning of unburned hydrocarbon residues of the military-technical vehicle.

The only objective way to confirm

changes in the standardized components of vehicle exhaust gases involve conducting a series of comparative measurements using a gas analyzer for gasoline internal combustion engines (or a smoke meter for diesel internal combustion engines) in order to record changes in the main components of exhaust gases: CO (carbon dioxide, toxin), CH (hydrocarbon residues, toxin), CO2 (carbon dioxide) and O2 (oxygen) or the “Smokiness” indicator for diesel internal combustion engines;

In addition, the exhaust gases contain Nitrogen Oxide and other components that are measured less frequently.

How to carry out comparative measurements using a gas analyzer.

Note:

protocol for measuring standardized components of vehicle exhaust gases in accordance with ST RK, see the section “FPDtech Protocols”.

Before connecting the “Super Torque” Pulse Module, the values of CO, CH, CO2 and O2 are measured and recorded.

Note:

when measuring and recording O2 values, it is necessary to take into account the generally accepted value of O2 content in the air, rounded, 21%;

the percentage of oxygen O2 in the Air-Fuel Mixture, AFC, with a stoichiometric ratio of 14.7/1 is equal to 19.66%.

After installing the Pulse Module, a second, intermediate, measurement and recording of the values of CO, CH, CO2 and O2 is carried out;

Before the second measurement, it is necessary to carry out a short adaptation run of the vehicle with the installed Pulse Module over a distance of 5-10 kilometers.

The third measurement and recording of the values of CO, CH, CO2 and O2 is carried out after passing 1200-1500 kilometers after installing the “Super Torque” Pulse Module.

The obtained data of the values of CO, CH, CO2 and O2 of three measurements are entered into the table of the Registration Form (see the section “FPDtech Protocols”).

Conclusion on Eco-efficiency

The operation of the “Super Torque” Pulse Module on a specific vehicle is based on the data of three measurements, which together show the dynamics of changes in the main indicators of the vehicle’s exhaust gases CO, CH, CO2 and O2 and lead to the final indicators of the environmental efficiency of the “Super Torque” Pulse Module.

Analysis of three tables.

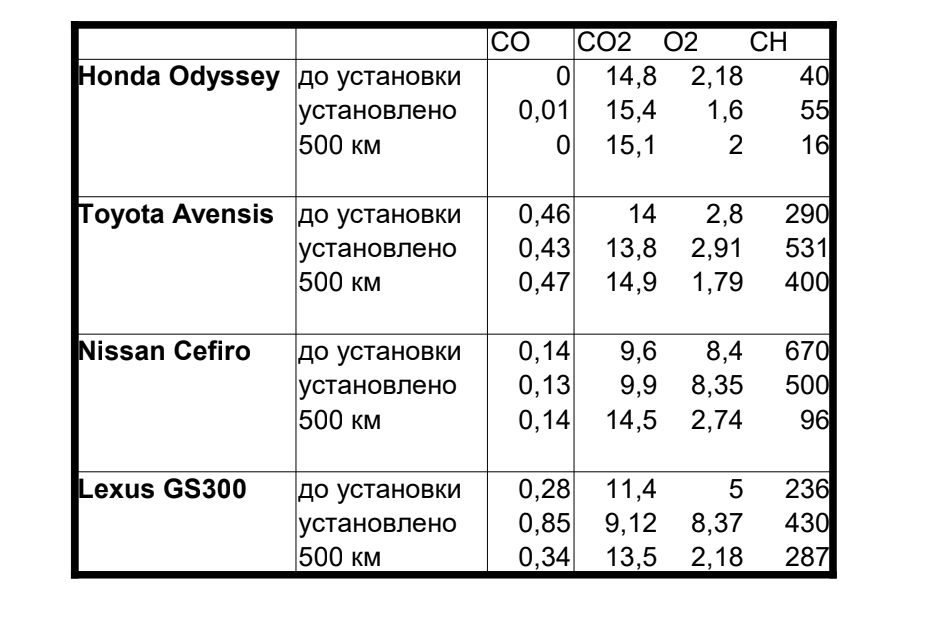

Table No. 1.

The purpose of the first comparative measurement:

determine a sufficient distance to complete the process of the most complete afterburning of unburned hydrocarbon residues of military-technical equipment.

Note:

measurements were carried out in the spring of 2019; vehicle data (year of manufacture, internal combustion engine volume, gearbox type, fuel type, total mileage) were not recorded; no preliminary diagnosis of errors and malfunctions was carried out; the presence or absence of a catalyst was not determined.

Changing the main indicators of CO, CH, CO2, O2 allows you to do the following

conclusion:

a distance of 400 kilometers is insufficient to complete the process of most complete afterburning of unburned hydrocarbon residues of military-technical equipment, which is based on the figures recorded by the gas analyzer, according to which

– excessively high level of oxygen consumption O2: remains, on average, less than 3%;

– excessively high level of carbon dioxide CO2: remains, on average, more than 13%;

– excessively high level of unburned toxic hydrocarbon residues of CH.

It is important to note

visible general dynamics of reduction in HF indicators for all cars.

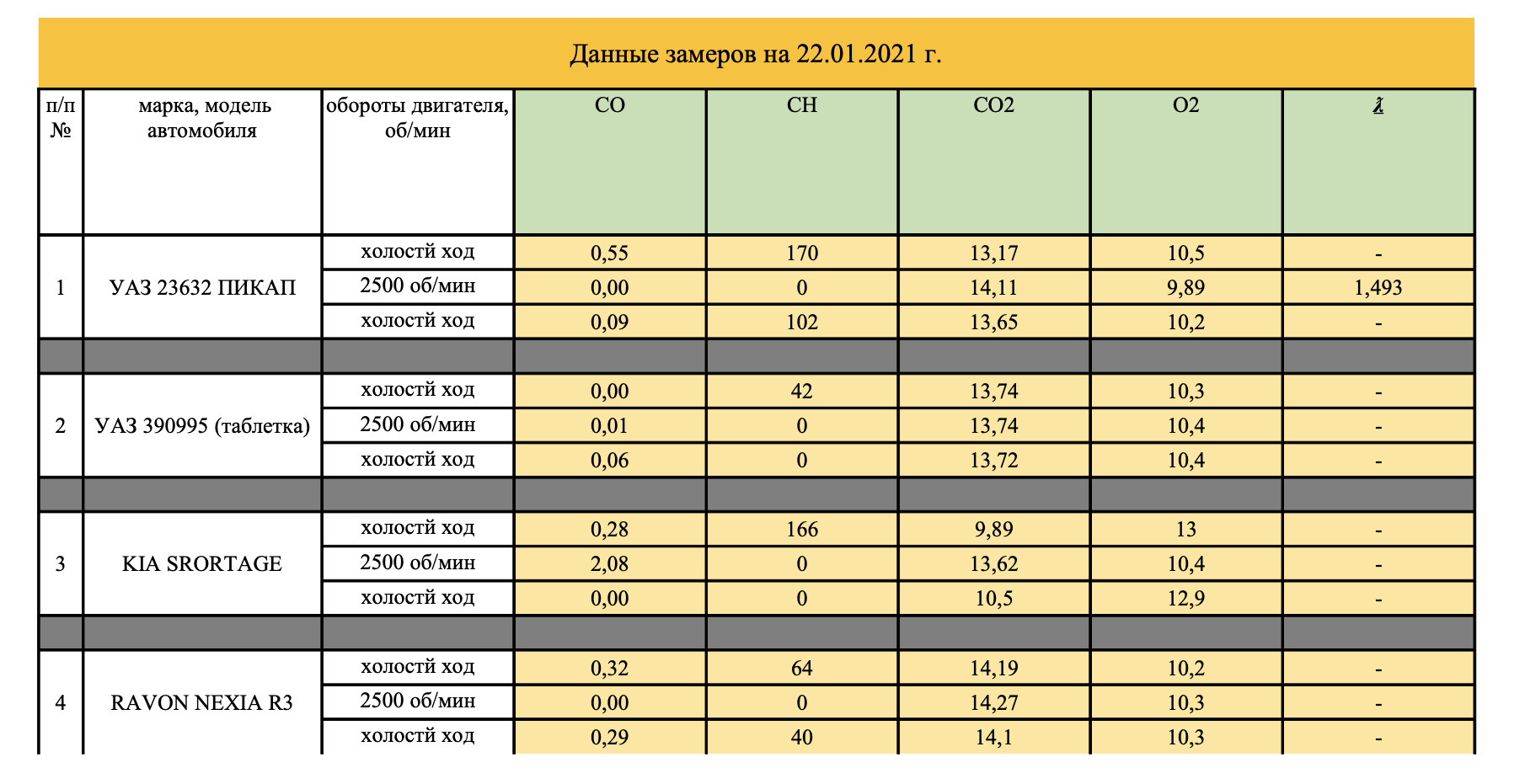

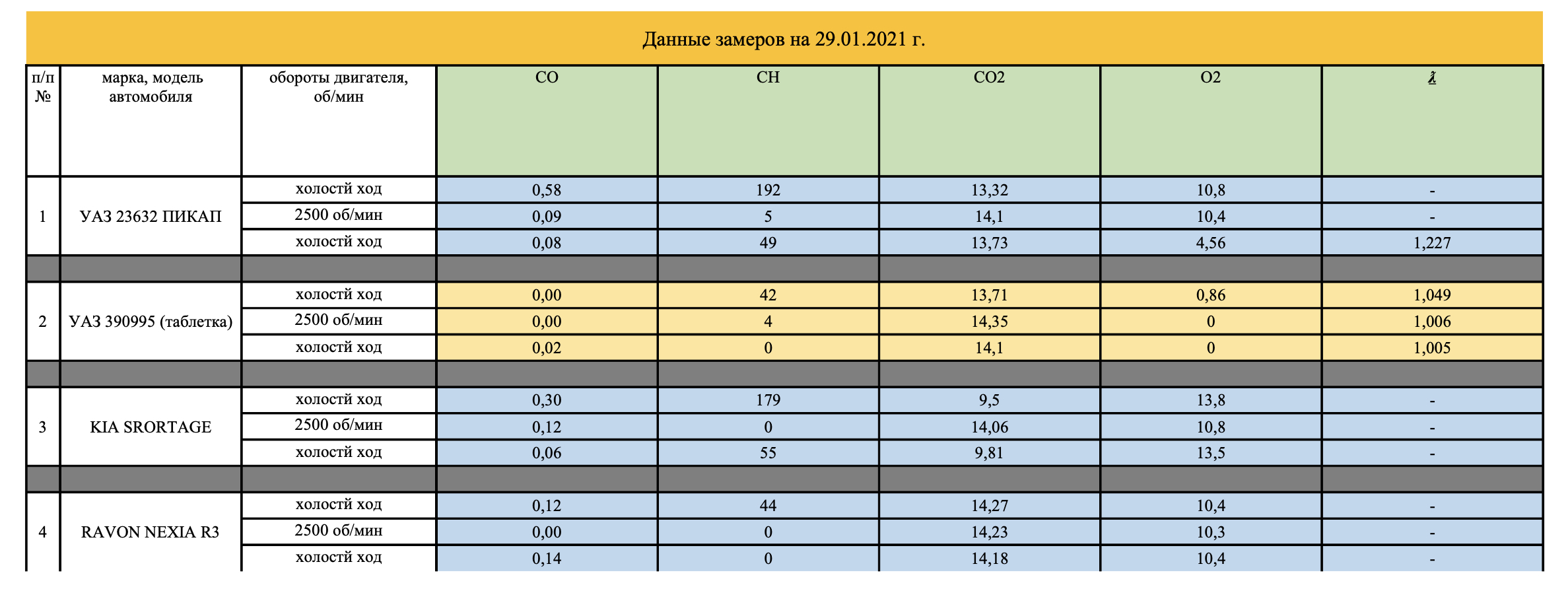

Table No. 2.

The purpose of the second comparative measurement:

carry out measurements in accordance with the ST RK Protocol, in which each measurement is carried out in the mode: “idle speed – high, 2500, speed – idle speed”;

record data and actual operational condition of vehicles;

determine a sufficient distance to complete the process of most complete afterburning of unburned hydrocarbon residues of CH;

carry out comparative measurements of fuel consumption.

Note:

a design operational defect of UAZ cars is expressed in the inhibited operation of the oxygen sensor, which has a fundamental impact on the CO indicator; the operational condition of these cars corresponds to the rating of “good”;

operational condition of cars of the KIA Sportage and RAVON Nexia brands

corresponds to a rating close to “weakly satisfactory”.

Conditions for taking measurements:

measurements were carried out in January 2021; To comply with the conditions of the measurement protocol in accordance with the requirements of the ST RK (air temperature must be above “0” degrees Celsius), measurements were carried out in a garage room with the air temperature required for measurements.

For the measurement results

a significant impact was exerted by the insufficient driving distance to complete the process of the most complete afterburning of unburned hydrocarbon residues of CH due to the early termination of the measurement by the decision of the party that provided these vehicles for measurements.

Note:

UAZ and RAVON Nexia vehicles are service vehicles.

Changing the main indicators of CO, CH, CO2, O2 allows you to do the following

conclusions:

– excessively high level of oxygen consumption O2;

– excessively high level of carbon dioxide CO2;

– excessively high level of unburned toxic hydrocarbon residues of CH.

It is important to note:

parallel comparative measurements of fuel consumption confirmed fuel economy on all four cars.

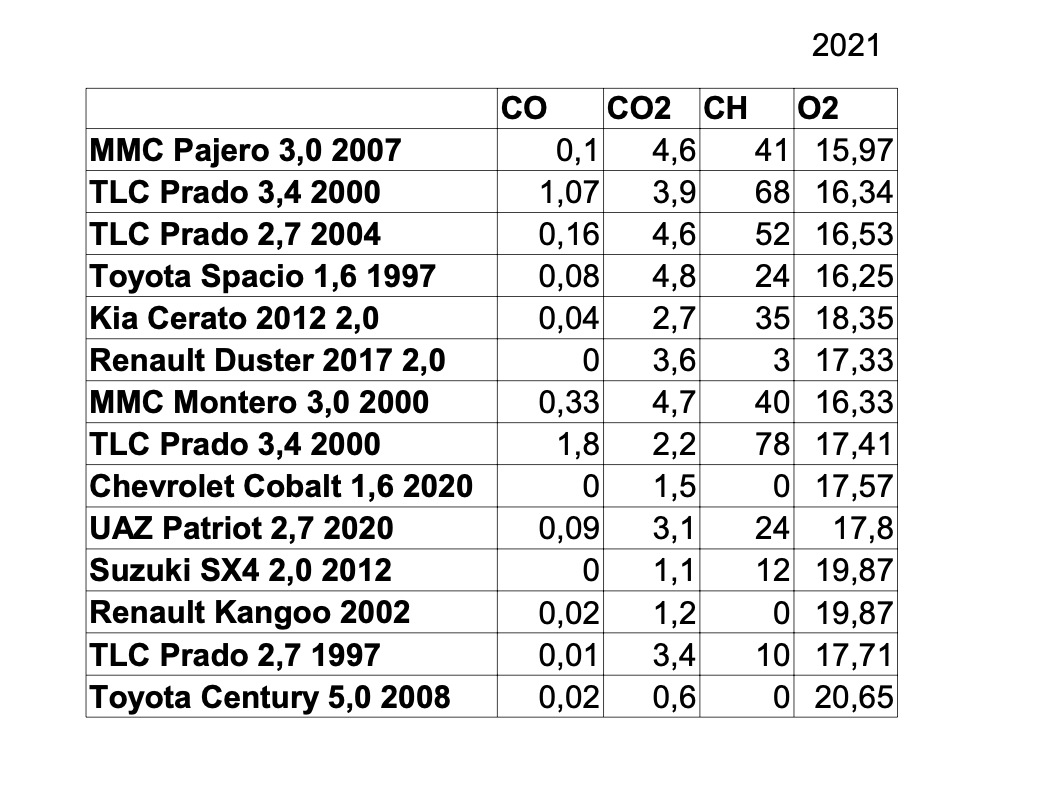

Table No. 3.

The purpose of the third comparative measurement:

obtaining data on vehicle exhaust gases with a guaranteed sufficient driving distance to complete the process of the most complete afterburning of unburned hydrocarbon residues of military-technical vehicles.

Note:

measurements were carried out during the period March-June 2021, as part of group comprehensive tests of a model of the new series of Pulse Module;

The measurements involved cars with a long-term, at least 2 years, experience in operating the “Super Torque” Pulse Module, with a mandatory driving distance after connecting the “Super Torque” Pulse Module over a distance of 1200-1500 kilometers, with an assessment of the operational condition of “good” “, without critical diagnostic errors, with recording of basic vehicle data (year of manufacture, engine size, gearbox type, fuel type).

Changes in the main indicators of CO, CH, CO2, O2

allows us to state the following:

– low oxygen consumption O2: on average, 4.56%;

– low content of carbon dioxide CO2: on average, 3.8%;

– low level of unburned toxic hydrocarbon residues of CH.

It is necessary to highlight the fact:

the low CH level in the first six cars was obtained in the absence of a catalyst;

low CO2 content proportionally corresponds to low oxygen consumption O2.

It is important to highlight:

in the third measurement, the indicators CO, CH, CO2 and O2 have a very small discrepancy between the indicators between the results of all cars;

high efficiency of combustion processes of VTS, where the main features – common to all internal combustion engines – are

reduced oxygen consumption O2 and

reduced carbon dioxide CO2 content

as part of exhaust automobile gases,

according to the emission data values of all cars that are close to each other.

General conclusion about Eco-efficiency

Pulse Module “Super Torque”

based on the following:

– fuel economy, confirmed objectively, is the most significant component of environmental efficiency in terms of volume;

– as a result of reducing each single dosage of VTS, a several-fold reduction in O2 consumption, CO2 and CH emissions is achieved.

It should be noted,

that the resulting environmental efficiency obviously requires a larger amount of data and a larger number of comparative measurements using the FPDtech protocol:

All interested parties are invited to carry out such measurements and obtain a larger array of data on the basis of mutually beneficial cooperation.

Important addition:

Along with data from comparative measurements of CO, CH, CO2, O2 indicators, it is necessary to note the importance of comparative measurements of fuel correction indicators, short-term and long-term.

These corrections show how close to the optimal stoichiometric ratio the formation of VTS occurs (14.7 kg of air per 1 kg of gasoline), at which the most complete combustion of VTS is achieved and, accordingly, maximum heat transfer, which determines the efficiency of the internal combustion engine for the production of Torque.

Note:

short-term and long-term fuel corrections set the maximum efficiency of the combustion process of military vehicles, subject to a minimum, up to 5%, deviation of the values of these corrections from each other.

To create the FPDtech Technical Regulations, observations, recording and analysis of indicators of short-term and long-term fuel corrections were carried out over a long period on different cars.

A similar nature of the data was noted: stability of correction indicators and stable retention of a minimum, up to 5%, deviation of the values of these corrections from each other.

The only objective reason for such stability can only be a reduction in each single dosage of VTS – the key point in the interaction of the “Super Torque” Pulse Module and the internal combustion engine.

Grand total:

in the fuel transport sector

the task of reducing the hydrocarbon footprint

becomes accessible and feasible

in a short period of time,

taking into account the fact that connecting the Module does not require any design changes on all types of fuel-fuelled vehicles.